Tags: حاضنة خفض خطوط الأنابيب, حاضنة خفض الأنابيب, معدات خفض خطوط الأنابيب, معدات مناولة الأنابيب, حاضنة رفع خطوط الأنابيب, حاضنة ناقلة للأنابيب, حاضنة أنابيب مزودة ببكرات, حاضنة خفض الأنابيب المزودة ببكرات, نظام رفع وخفض خطوط الأنابيب, حاضنة دعم الأنابيب, حاضنة خفض الأنابيب للخدمة الشاقة, حاضنة مزودة ببكرات من البولي يوريثين, مُصنِّع حاضنات تركيب الأنابيب, مورد حاضنات خفض خطوط الأنابيب, مُصدّر حاضنات خطوط الأنابيب, مُصنِّع حاضنات الأنابيب المزودة ببكرات, معدات بناء خطوط الأنابيب, حاضنة تركيب خطوط الأنابيب, حاضنة خفض خطوط أنابيب النفط والغاز, حاضنة خفض خطوط الأنابيب للمصافي, حاضنة لبناء خطوط أنابيب النفط والغاز, معدات تركيب خطوط أنابيب النفط والغاز, مُصنِّع حاضنات خفض خطوط الأنابيب, مورد حاضنات خفض خطوط الأنابيب, مُصدّر حاضنات خفض خطوط الأنابيب, حاضنة خفض خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة خفض الأنابيب في الإمارات العربية المتحدة, معدات خفض خطوط الأنابيب في الإمارات العربية المتحدة, معدات مناولة الأنابيب في الإمارات العربية المتحدة, حاضنة رفع خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة ناقلة للأنابيب في الإمارات العربية المتحدة, حاضنة أنابيب مزودة ببكرات في الإمارات العربية المتحدة, حاضنة خفض الأنابيب المزودة ببكرات في الإمارات العربية المتحدة, نظام رفع وخفض خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة دعم الأنابيب في الإمارات العربية المتحدة, حاضنة خفض الأنابيب للخدمة الشاقة في الإمارات العربية المتحدة, حاضنة مزودة ببكرات من البولي يوريثين في الإمارات العربية المتحدة, مُصنِّع حاضنات تركيب الأنابيب في الإمارات العربية المتحدة, مورد حاضنات خفض خطوط الأنابيب في الإمارات العربية المتحدة, مُصدّر حاضنات خطوط الأنابيب في الإمارات العربية المتحدة, مُصنِّع حاضنات الأنابيب المزودة ببكرات في الإمارات العربية المتحدة, معدات بناء خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة تركيب خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة خفض خطوط أنابيب النفط والغاز في الإمارات العربية المتحدة, حاضنة خفض خطوط الأنابيب للمصافي في الإمارات العربية المتحدة, حاضنة لبناء خطوط أنابيب النفط والغاز في الإمارات العربية المتحدة, معدات تركيب خطوط أنابيب النفط والغاز في الإمارات العربية المتحدة, مُصنِّع حاضنات خفض خطوط الأنابيب في الإمارات العربية المتحدة, مورد حاضنات خفض خطوط الأنابيب في الإمارات العربية المتحدة, مُصدّر حاضنات خفض خطوط الأنابيب في الإمارات العربية المتحدة, حاضنة خفض خطوط الأنابيب في المملكة العربية السعودية, حاضنة خفض الأنابيب في المملكة العربية السعودية, معدات خفض خطوط الأنابيب في المملكة العربية السعودية, معدات مناولة الأنابيب في المملكة العربية السعودية, حاضنة رفع خطوط الأنابيب في المملكة العربية السعودية, حاضنة ناقلة للأنابيب في المملكة العربية السعودية, حاضنة أنابيب مزودة ببكرات في المملكة العربية السعودية, حاضنة خفض الأنابيب المزودة ببكرات في المملكة العربية السعودية, نظام رفع وخفض خطوط الأنابيب في المملكة العربية السعودية, حاضنة دعم الأنابيب في المملكة العربية السعودية, حاضنة خفض الأنابيب للخدمة الشاقة في المملكة العربية السعودية, حاضنة مزودة ببكرات من البولي يوريثين في المملكة العربية السعودية, مُصنِّع حاضنات تركيب الأنابيب في المملكة العربية السعودية, مورد حاضنات خفض خطوط الأنابيب في المملكة العربية السعودية, مُصدّر حاضنات خطوط الأنابيب في المملكة العربية السعودية, مُصنِّع حاضنات الأنابيب المزودة ببكرات في المملكة العربية السعودية, معدات بناء خطوط الأنابيب في المملكة العربية السعودية, حاضنة تركيب خطوط الأنابيب في المملكة العربية السعودية, حاضنة خفض خطوط أنابيب النفط والغاز في المملكة العربية السعودية, حاضنة خفض خطوط الأنابيب للمصافي في المملكة العربية السعودية, حاضنة لبناء خطوط أنابيب النفط والغاز في المملكة العربية السعودية, معدات تركيب خطوط أنابيب النفط والغاز في المملكة العربية السعودية, مُصنِّع حاضنات خفض خطوط الأنابيب في المملكة العربية السعودية, مورد حاضنات خفض خطوط الأنابيب في المملكة العربية السعودية, مُصدّر حاضنات خفض خطوط الأنابيب في المملكة العربية السعودية, حاضنة خفض خطوط الأنابيب في قطر, حاضنة خفض الأنابيب في قطر, معدات خفض خطوط الأنابيب في قطر, معدات مناولة الأنابيب في قطر, حاضنة رفع خطوط الأنابيب في قطر, حاضنة ناقلة للأنابيب في قطر, حاضنة أنابيب مزودة ببكرات في قطر, حاضنة خفض الأنابيب المزودة ببكرات في قطر, نظام رفع وخفض خطوط الأنابيب في قطر, حاضنة دعم الأنابيب في قطر, حاضنة خفض الأنابيب للخدمة الشاقة في قطر, حاضنة مزودة ببكرات من البولي يوريثين في قطر, مُصنِّع حاضنات تركيب الأنابيب في قطر, مورد حاضنات خفض خطوط الأنابيب في قطر, مُصدّر حاضنات خطوط الأنابيب في قطر, مُصنِّع حاضنات الأنابيب المزودة ببكرات في قطر, معدات بناء خطوط الأنابيب في قطر, حاضنة تركيب خطوط الأنابيب في قطر, حاضنة خفض خطوط أنابيب النفط والغاز في قطر, حاضنة خفض خطوط الأنابيب للمصافي في قطر, حاضنة لبناء خطوط أنابيب النفط والغاز في قطر, معدات تركيب خطوط أنابيب النفط والغاز في قطر, مُصنِّع حاضنات خفض خطوط الأنابيب في قطر, مورد حاضنات خفض خطوط الأنابيب في قطر, مُصدّر حاضنات خفض خطوط الأنابيب في قطر, حاضنة خفض خطوط الأنابيب في سلطنة عُمان, حاضنة خفض الأنابيب في سلطنة عُمان, معدات خفض خطوط الأنابيب في سلطنة عُمان, معدات مناولة الأنابيب في سلطنة عُمان, حاضنة رفع خطوط الأنابيب في سلطنة عُمان, حاضنة ناقلة للأنابيب في سلطنة عُمان, حاضنة أنابيب مزودة ببكرات في سلطنة عُمان, حاضنة خفض الأنابيب المزودة ببكرات في سلطنة عُمان, نظام رفع وخفض خطوط الأنابيب في سلطنة عُمان, حاضنة دعم الأنابيب في سلطنة عُمان, حاضنة خفض الأنابيب للخدمة الشاقة في سلطنة عُمان, حاضنة مزودة ببكرات من البولي يوريثين في سلطنة عُمان, مُصنِّع حاضنات تركيب الأنابيب في سلطنة عُمان, مورد حاضنات خفض خطوط الأنابيب في سلطنة عُمان, مُصدّر حاضنات خطوط الأنابيب في سلطنة عُمان, مُصنِّع حاضنات الأنابيب المزودة ببكرات في سلطنة عُمان, معدات بناء خطوط الأنابيب في سلطنة عُمان, حاضنة تركيب خطوط الأنابيب في سلطنة عُمان, حاضنة خفض خطوط أنابيب النفط والغاز في سلطنة عُمان, حاضنة خفض خطوط الأنابيب للمصافي في سلطنة عُمان, حاضنة لبناء خطوط أنابيب النفط والغاز في سلطنة عُمان, معدات تركيب خطوط أنابيب النفط والغاز في سلطنة عُمان, مُصنِّع حاضنات خفض خطوط الأنابيب في سلطنة عُمان, مورد حاضنات خفض خطوط الأنابيب في سلطنة عُمان, مُصدّر حاضنات خفض خطوط الأنابيب في سلطنة عُمان, حاضنة خفض خطوط الأنابيب في الكويت, حاضنة خفض الأنابيب في الكويت, معدات خفض خطوط الأنابيب في الكويت, معدات مناولة الأنابيب في الكويت, حاضنة رفع خطوط الأنابيب في الكويت, حاضنة ناقلة للأنابيب في الكويت, حاضنة أنابيب مزودة ببكرات في الكويت, حاضنة خفض الأنابيب المزودة ببكرات في الكويت, نظام رفع وخفض خطوط الأنابيب في الكويت, حاضنة دعم الأنابيب في الكويت, حاضنة خفض الأنابيب للخدمة الشاقة في الكويت, حاضنة مزودة ببكرات من البولي يوريثين في الكويت, مُصنِّع حاضنات تركيب الأنابيب في الكويت, مورد حاضنات خفض خطوط الأنابيب في الكويت, مُصدّر حاضنات خطوط الأنابيب في الكويت, مُصنِّع حاضنات الأنابيب المزودة ببكرات في الكويت, معدات بناء خطوط الأنابيب في الكويت, حاضنة تركيب خطوط الأنابيب في الكويت, حاضنة خفض خطوط أنابيب النفط والغاز في الكويت, حاضنة خفض خطوط الأنابيب للمصافي في الكويت, حاضنة لبناء خطوط أنابيب النفط والغاز في الكويت, معدات تركيب خطوط أنابيب النفط والغاز في الكويت, مُصنِّع حاضنات خفض خطوط الأنابيب في الكويت, مورد حاضنات خفض خطوط الأنابيب في الكويت, مُصدّر حاضنات خفض خطوط الأنابيب في الكويت, حاضنة خفض خطوط الأنابيب في البحرين, حاضنة خفض الأنابيب في البحرين, معدات خفض خطوط الأنابيب في البحرين, معدات مناولة الأنابيب في البحرين, حاضنة رفع خطوط الأنابيب في البحرين, حاضنة ناقلة للأنابيب في البحرين, حاضنة أنابيب مزودة ببكرات في البحرين, حاضنة خفض الأنابيب المزودة ببكرات في البحرين, نظام رفع وخفض خطوط الأنابيب في البحرين, حاضنة دعم الأنابيب في البحرين, حاضنة خفض الأنابيب للخدمة الشاقة في البحرين, حاضنة مزودة ببكرات من البولي يوريثين في البحرين, مُصنِّع حاضنات تركيب الأنابيب في البحرين, مورد حاضنات خفض خطوط الأنابيب في البحرين, مُصدّر حاضنات خطوط الأنابيب في البحرين, مُصنِّع حاضنات الأنابيب المزودة ببكرات في البحرين, معدات بناء خطوط الأنابيب في البحرين, حاضنة تركيب خطوط الأنابيب في البحرين, حاضنة خفض خطوط أنابيب النفط والغاز في البحرين, حاضنة خفض خطوط الأنابيب للمصافي في البحرين, حاضنة لبناء خطوط أنابيب النفط والغاز في البحرين, معدات تركيب خطوط أنابيب النفط والغاز في البحرين, مُصنِّع حاضنات خفض خطوط الأنابيب في البحرين, مورد حاضنات خفض خطوط الأنابيب في البحرين, مُصدّر حاضنات خفض خطوط الأنابيب في البحرين, حاضنة خفض خطوط الأنابيب في مصر, حاضنة خفض الأنابيب في مصر, معدات خفض خطوط الأنابيب في مصر, معدات مناولة الأنابيب في مصر, حاضنة رفع خطوط الأنابيب في مصر, حاضنة ناقلة للأنابيب في مصر, حاضنة أنابيب مزودة ببكرات في مصر, حاضنة خفض الأنابيب المزودة ببكرات في مصر, نظام رفع وخفض خطوط الأنابيب في مصر, حاضنة دعم الأنابيب في مصر, حاضنة خفض الأنابيب للخدمة الشاقة في مصر, حاضنة مزودة ببكرات من البولي يوريثين في مصر, مُصنِّع حاضنات تركيب الأنابيب في مصر, مورد حاضنات خفض خطوط الأنابيب في مصر, مُصدّر حاضنات خطوط الأنابيب في مصر, مُصنِّع حاضنات الأنابيب المزودة ببكرات في مصر, معدات بناء خطوط الأنابيب في مصر, حاضنة تركيب خطوط الأنابيب في مصر, حاضنة خفض خطوط أنابيب النفط والغاز في مصر, حاضنة خفض خطوط الأنابيب للمصافي في مصر, حاضنة لبناء خطوط أنابيب النفط والغاز في مصر, معدات تركيب خطوط أنابيب النفط والغاز في مصر, مُصنِّع حاضنات خفض خطوط الأنابيب في مصر, مورد حاضنات خفض خطوط الأنابيب في مصر, مُصدّر حاضنات خفض خطوط الأنابيب في مصر, حاضنة خفض خطوط الأنابيب في الجزائر, حاضنة خفض الأنابيب في الجزائر, معدات خفض خطوط الأنابيب في الجزائر, معدات مناولة الأنابيب في الجزائر, حاضنة رفع خطوط الأنابيب في الجزائر, حاضنة ناقلة للأنابيب في الجزائر, حاضنة أنابيب مزودة ببكرات في الجزائر, حاضنة خفض الأنابيب المزودة ببكرات في الجزائر, نظام رفع وخفض خطوط الأنابيب في الجزائر, حاضنة دعم الأنابيب في الجزائر, حاضنة خفض الأنابيب للخدمة الشاقة في الجزائر, حاضنة مزودة ببكرات من البولي يوريثين في الجزائر, مُصنِّع حاضنات تركيب الأنابيب في الجزائر, مورد حاضنات خفض خطوط الأنابيب في الجزائر, مُصدّر حاضنات خطوط الأنابيب في الجزائر, مُصنِّع حاضنات الأنابيب المزودة ببكرات في الجزائر, معدات بناء خطوط الأنابيب في الجزائر, حاضنة تركيب خطوط الأنابيب في الجزائر, حاضنة خفض خطوط أنابيب النفط والغاز في الجزائر, حاضنة خفض خطوط الأنابيب للمصافي في الجزائر, حاضنة لبناء خطوط أنابيب النفط والغاز في الجزائر, معدات تركيب خطوط أنابيب النفط والغاز في الجزائر, مُصنِّع حاضنات خفض خطوط الأنابيب في الجزائر, مورد حاضنات خفض خطوط الأنابيب في الجزائر, مُصدّر حاضنات خفض خطوط الأنابيب في الجزائر, حاضنة خفض خطوط الأنابيب في ليبيا, حاضنة خفض الأنابيب في ليبيا, معدات خفض خطوط الأنابيب في ليبيا, معدات مناولة الأنابيب في ليبيا, حاضنة رفع خطوط الأنابيب في ليبيا, حاضنة ناقلة للأنابيب في ليبيا, حاضنة أنابيب مزودة ببكرات في ليبيا, حاضنة خفض الأنابيب المزودة ببكرات في ليبيا, نظام رفع وخفض خطوط الأنابيب في ليبيا, حاضنة دعم الأنابيب في ليبيا, حاضنة خفض الأنابيب للخدمة الشاقة في ليبيا, حاضنة مزودة ببكرات من البولي يوريثين في ليبيا, مُصنِّع حاضنات تركيب الأنابيب في ليبيا, مورد حاضنات خفض خطوط الأنابيب في ليبيا, مُصدّر حاضنات خطوط الأنابيب في ليبيا, مُصنِّع حاضنات الأنابيب المزودة ببكرات في ليبيا, معدات بناء خطوط الأنابيب في ليبيا, حاضنة تركيب خطوط الأنابيب في ليبيا, حاضنة خفض خطوط أنابيب النفط والغاز في ليبيا, حاضنة خفض خطوط الأنابيب للمصافي في ليبيا, حاضنة لبناء خطوط أنابيب النفط والغاز في ليبيا, معدات تركيب خطوط أنابيب النفط والغاز في ليبيا, مُصنِّع حاضنات خفض خطوط الأنابيب في ليبيا, مورد حاضنات خفض خطوط الأنابيب في ليبيا, مُصدّر حاضنات خفض خطوط الأنابيب في ليبيا

Pipe Roller with Motor Drive

Pipe Roller with Motor Drive Manufacturer

SPM Equipment stands out as a leading pipe roller with motor drive manufacturer in India, providing cutting-edge solutions designed to enhance the efficiency and precision of pipe handling and welding operations. Our pipe rollers with motor drives are engineered to offer smooth and controlled rotation of pipes, enabling seamless and accurate welding processes. Known for our commitment to quality and innovation, we have built a reputation as a trusted partner in the industrial sector.

Our pipe roller with motor drive products are crafted with advanced motorized systems that ensure consistent and reliable performance. These motor-driven rollers allow for precise control of pipe movement, reducing manual labour and enhancing productivity. Built with high-quality materials, they are robust and durable, capable of handling heavy-duty applications and enduring harsh industrial environments. The motorized drive adds an extra layer of efficiency, making these rollers ideal for large-scale projects that demand consistent performance and high precision.

As a top pipe roller with motor drive manufacturer in India, SPM Equipment is dedicated to delivering innovative solutions that meet the evolving needs of the industry. Our products are designed to optimize workflow, reduce downtime, and improve overall operational efficiency. Whether for construction, oil and gas, or other industrial applications, our motor-driven rollers provide the reliability and performance needed for successful project completion.

In addition to our manufacturing capabilities, we are a prominent pipe roller with motor drive exporter in India, supplying our high-performance products to clients worldwide. Recognized for their superior quality and durability, our rollers have made SPM Equipment a preferred choice for industrial pipe handling solutions. Trust SPM Equipment for your pipe roller needs, and benefit from the quality, innovation, and expertise that distinguish us in the market.

Feature & Advantages

- SPM Equipment's Pipe Roller with Motor Drive is versatile, accommodating pipes ranging from 2” To Above in diameter.

- Equipped with a powerful motor drive, it ensures efficient and controlled rotation of pipes during welding or fabrication processes.

- The motor drive feature eliminates the need for manual rotation, reducing labor and increasing productivity.

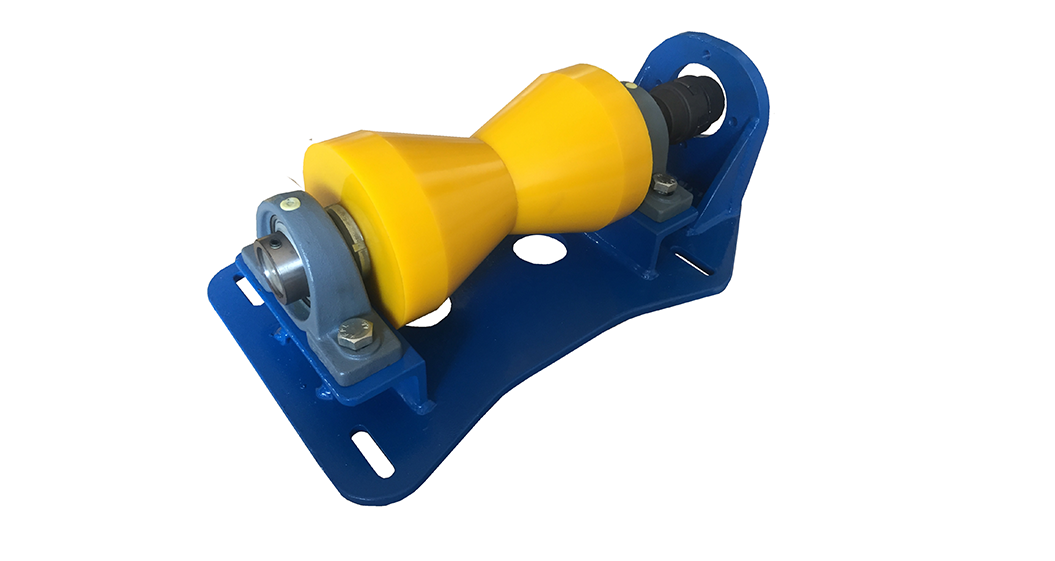

- Designed with durability in mind, it can withstand heavy-duty usage in demanding industrial environments.

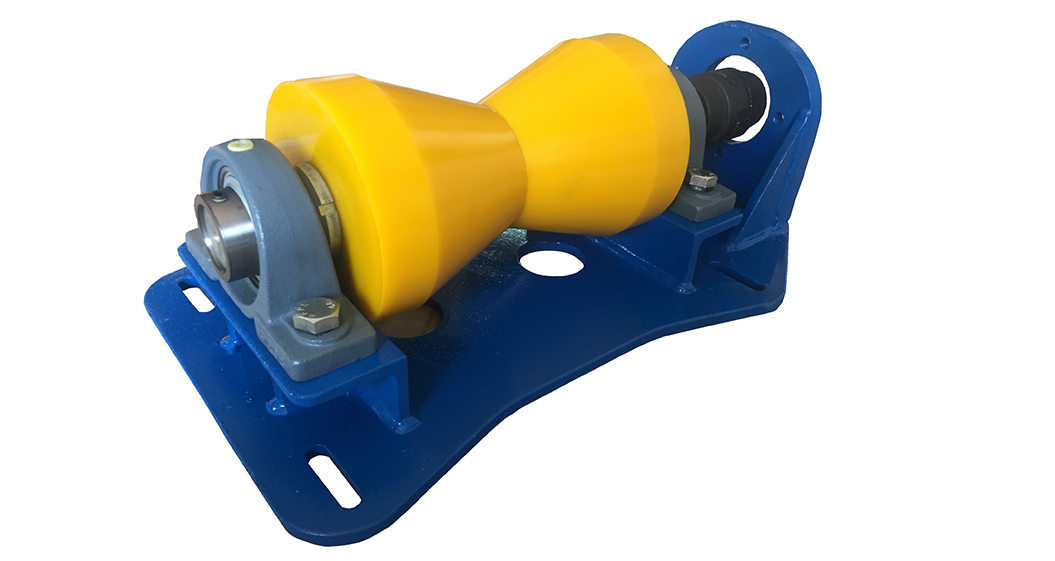

- The adjustable roller positions allow for precise alignment of pipes, ensuring accurate welding and fabrication results.

- Its robust construction and stable base provide stability and support for pipes of varying sizes and weights.

- The motor drive system offers consistent and uniform rotation speeds, promoting uniform weld bead formation.

- With ergonomic controls and user-friendly operation, it enhances worker safety and ease of use.

- Suitable for both indoor and outdoor applications, offering flexibility in various work environments.

- Low maintenance requirements contribute to reduced downtime and operational costs.

- Supported by SPM Equipment's expertise and commitment to quality, providing reliable performance and customer satisfaction.

Company Profile

SPM Equipment stands at the forefront of innovation and excellence in the pipeline industry as a leading CS pipe welding equipment manufacturer, exporter, and supplier across Asia. We are dedicated to delivering top-notch products that cater to the diverse needs of our clients, ensuring efficient, precise, and durable solutions for every stage of pipeline construction and maintenance.

Why Choose SPM Equipment for

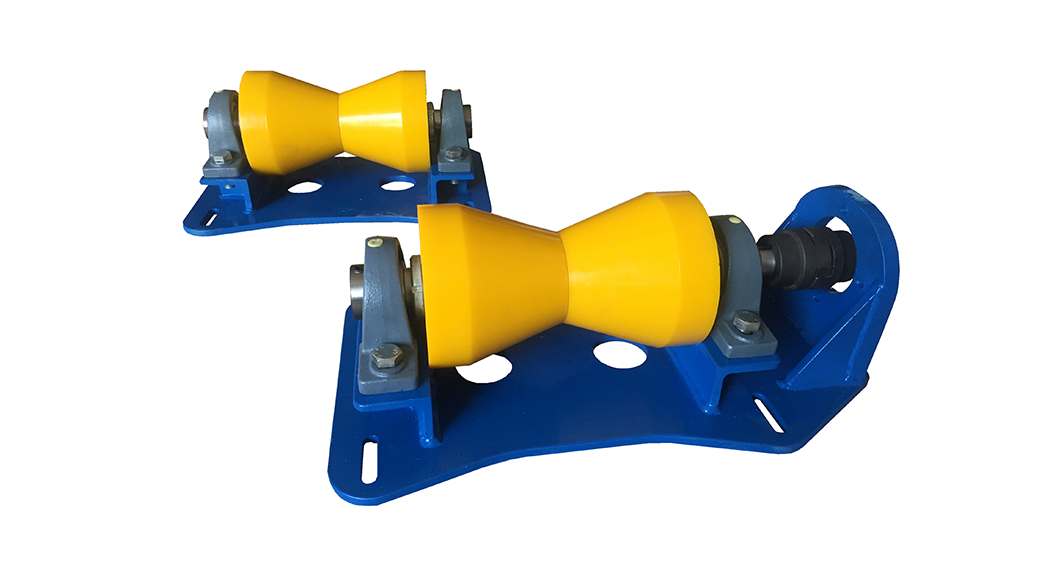

Pipe Roller Cone Type PU Coated?

Choosing SPM Equipment for your Pipe Roller Cone Type PU Coated needs guarantees superior quality and excellent reliability. Our extensive experience in the oil and gas pipeline industry has equipped us with the knowledge and expertise to design and manufacture products that meet the highest standards. To guarantee that our pipe rollers (PU Coated) give maximum performance and durability, we use only the best materials and apply precise quality control procedures. Additionally, our products are designed with the user in mind, offering ease of use and efficiency on the job site. Our global presence and reputation as a leading exporter further attest to our commitment to customer satisfaction and excellence. When you choose SPM Equipment, you are choosing an expert who is committed to ensuring the success of your project with innovative, reliable, and high-quality pipeline equipment.

An ISO 9001:2015 Certified Company

Australia

France

Kuwait

Malaysia

Saudi Arabia

Singapore

USA

UAE

Tanzania

Switzerland

Qatar

South Korea

Bangladesh

Czech Republic

Netherlands

Kazakhstan

Mongolia

Nigeria

Vietnam

Oman

Thailand

Mexico

Papua New Guinea

Tunisia

Libya

Italy

Trinidad and Tobago

Turkey

Indonesia

Algeria

FAQ: Frequently Asked Questions

To maintain a Pipe Roller with Motor Drive, regularly inspect the machine for any signs of wear or damage, ensure proper lubrication of the rollers and motor, and follow the manufacturer's recommended maintenance schedule. Additionally, ensure that the machine is stored properly when not in use to prevent damage or corrosion.

A Pipe Roller with Motor Drive can typically handle pipes of various sizes and materials, including carbon steel, stainless steel, and aluminum. The specific capabilities will depend on the particular model and manufacturer.

The benefits of using a Pipe Roller with Motor Drive include increased productivity and efficiency during fabrication processes, reduced risk of injury to workers from manual handling of heavy pipes, and improved quality of welds due to more precise positioning and rotation of the pipe.